Building & Construction

Electricals, Electronics & IT

Industrial Supplies & Engineered Products

Machinery & Mechanical Equipment

Packaging, Printing & Office Supplies

All Categories

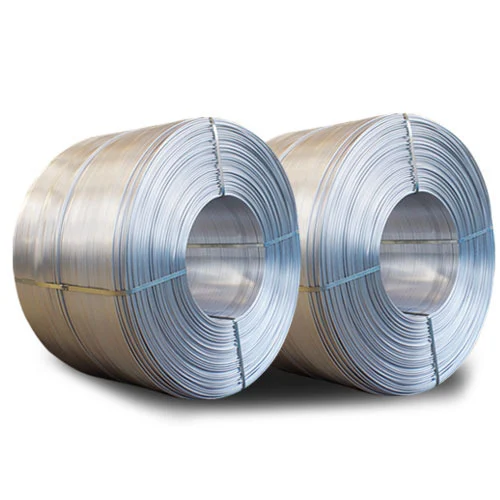

Aluminium Wire

32 results Price Available

Price Available

Aluminium Wire

32 results

Price Available

Price Available

Price Available

Price Available

300K+ Bought

300K+ Bought

Price on request

SAMPAT ALLUMINIUM PVT LTD

Ahmedabad, GJ

Ahmedabad, GJ

10K+ Bought

10K+ Bought

Price on request

VOLTAMP POWERTECH

Nagpur, MH

Nagpur, MH

Price on request

Metal Trading

Aurangabad, MH

Aurangabad, MH

+1 Variant(s)

Price on request

Arfin India Limited

Gandhinagar, GJ

Gandhinagar, GJ

+1 Variant(s)

Price on request

Shri Tapodhani Aluminium Trading Company

Central Delhi, DL

Central Delhi, DL

+1 more seller(s)

+1 Variant(s)

Price on request

Shri Tapodhani Aluminium Trading Company

Central Delhi, DL

Central Delhi, DL

+1 more seller(s)

+2 Variant(s)

Price on request

khandelwal electro products

Jaipur, RJ

Jaipur, RJ

Price on request

THE COIMBATORE METAL MART

Coimbatore, TN

Coimbatore, TN

Price on request

KJV ALLOY CONDUCTORS PRIVATE LIMITED

Chhindwara, MP

Chhindwara, MP

10K+ Bought

10K+ Bought

Price on request

SAUREN INDUSTRIES PRIVATE LIMITED

Nagpur, MH

Nagpur, MH

+5 Variant(s)

20K+ Bought

20K+ Bought

Price on request

Aditya Metal Industries

Gandhinagar, GJ

Gandhinagar, GJ

Price on request

GANPATI INDUSTRIES

Jaipur, RJ

Jaipur, RJ

Price on request

Hindustan Wire Industries

S A S Nagar, PB

S A S Nagar, PB

+1 Variant(s)

Price on request

Hindustan Wire Industries

S A S Nagar, PB

S A S Nagar, PB

Price on request

SARJA ELECTRICAL AND ENGINEERING SERVICE PRIVATE LIMITED

Nagpur, MH

Nagpur, MH

Price on request

Samsoft Techno Engineers

Central Delhi, DL

Central Delhi, DL

Price on request

Savariya industries

Surat, GJ

Surat, GJ

Price on request

SRI THAMARAI ELECTRICALS

Chengalpattu, TN

Chengalpattu, TN

8K+ Bought

8K+ Bought

Price on request

Vanshika Metal Industries Pvt Ltd

Gandhinagar, GJ

Gandhinagar, GJ

20+ Bought

20+ Bought

Price on request

HEADSUP B2B PRIVATE LIMITED

SOUTH DELHI, DL

SOUTH DELHI, DL

10K+ Bought

10K+ Bought

Price on request

JMJ ALLOY AND STEEL WIRES

Nanded, MH

Nanded, MH

Price on request

Joes Engineers

Chandigarh, CH

Chandigarh, CH

Price on request

Linear Energy Pvt Ltd

New Delhi, DL

New Delhi, DL

+1 Variant(s)

Price on request

WINCAB INDUSTRIES PRIVATE LIMITED

Dhar, MP

Dhar, MP

Price on request

WINCAB INDUSTRIES PRIVATE LIMITED

Dhar, MP

Dhar, MP

Price on request

Savariya industries

Surat, GJ

Surat, GJ

Price on request

WINCAB INDUSTRIES PRIVATE LIMITED

Dhar, MP

Dhar, MP